- We have senior tooling designer to provide our customer the service of professional feasibility study both on tooling and product, we are focus on the injection tooling for Automotive, home appliance and other product.

- Europe technologic criterion.

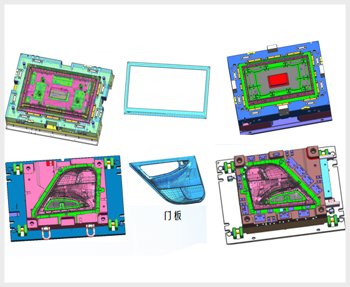

- Capacity of feasibility study with customer on product design stage.

- Tooling quotation based on tooling design.

- Mold flow with distortion analysis.

- Tooling design with 3D and 2D.

- Technologic analysis before tooling manufacturing.

- CAD/CAM soft ware£º UniGraphics. Support: Catia/Soildworks/Proe/AutoCAD/WorkNC/Sescol/etc.

- Steel usage£º1.2738HH,P20HH,8407,1.2343£¬1.2344£¬1.2767£¬NAK80£¬420ss,Moldmax,etc.

- Resin usage£ºPP,PP+EPDM+T20, PC,ABS,PC+ABS,POM,PPS,TPE, PA66,PA66+GF(10-50%),PEEK,etc.

- Hot runner system£ºMold Master,Synventive,Husky, Incoe,Mastip,Yudo,etc.

- Tooling surface treat: SPI, Mold Tech, Tenibac-Graphion and TanaZawa Hakkosha,Nihon graining, VDI CH etc.

Address: Taoziyuan High Technology Zone Hengli Town Dongguan City,Guangdong province, China

Post Code:523475 Tel:+86-769-89055988 Fax:+86-769-89055877 E-mail:market@qinhantech.com

Qinhan Tech All Right Reserved. ©

Company Mailbox